Introduction

Choosing the right Foundry Coke can make or break your casting process. Not all suppliers deliver the same quality, consistency, or specifications. In this article, we dive into how to compare top suppliers, evaluate product features, and make informed decisions. You’ll discover tips to secure reliable, high-performance coke for flawless metal casting results.

What is Foundry Coke?

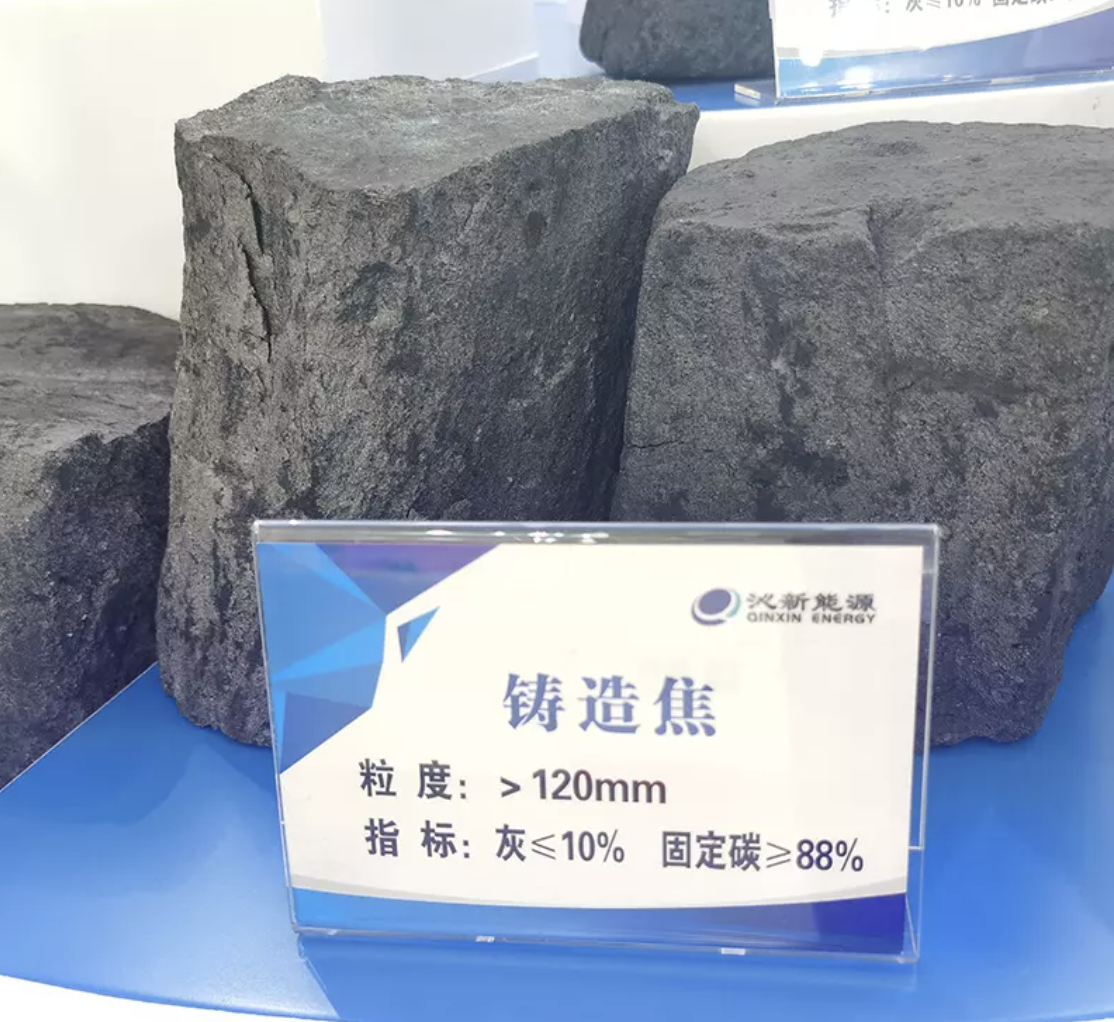

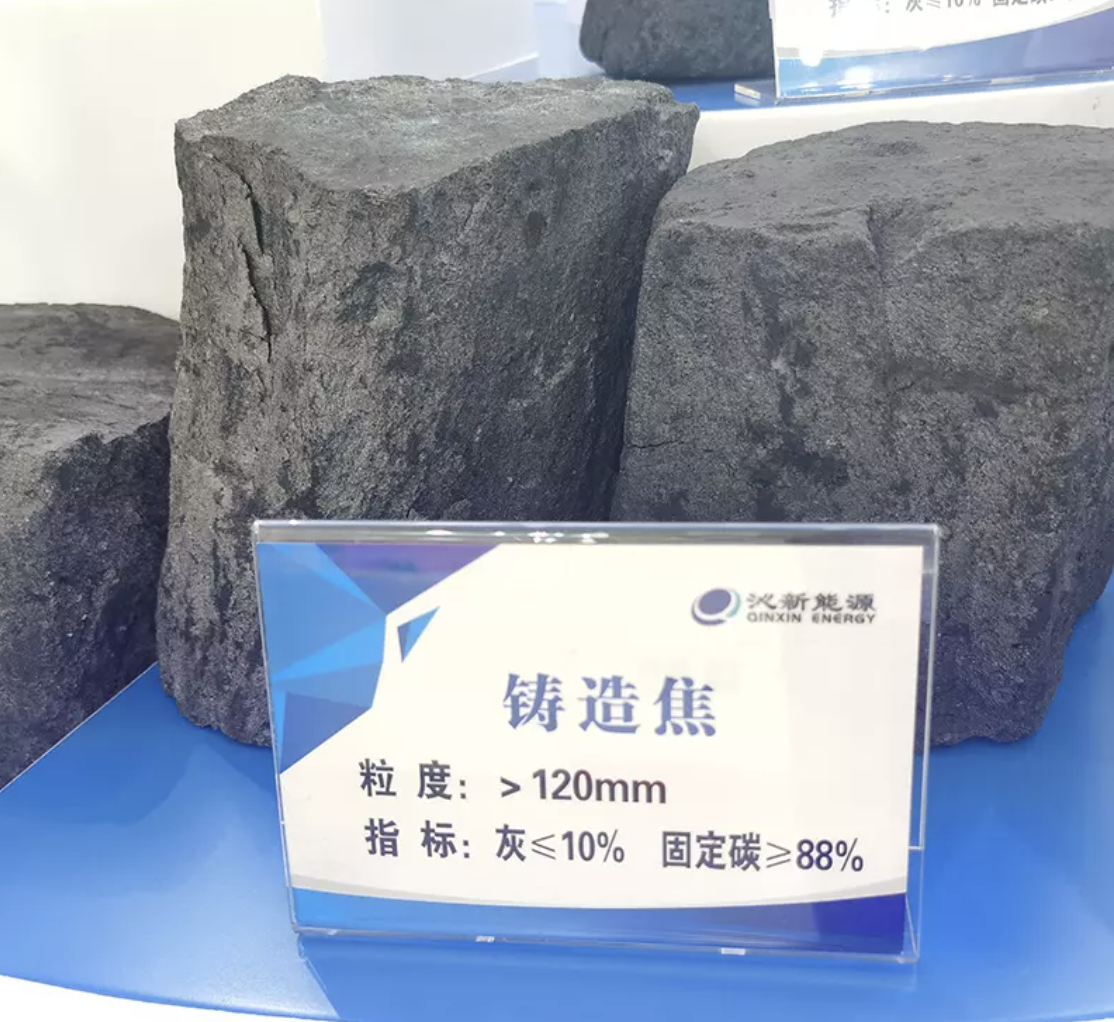

Foundry coke is a high-carbon fuel produced by carbonizing coking coal in an oxygen-free environment. This process removes volatile compounds and produces dense, uniform blocks with high fixed carbon, low sulfur, and minimal ash. Its thermal stability and moderate reactivity make it ideal for industrial metal casting, including both ferrous and non-ferrous alloys.

Unlike metallurgical coke, which is often used in steelmaking blast furnaces, foundry coke emphasizes structural strength, uniform size, and low impurity levels. These characteristics allow it to support cupola furnaces for long periods without collapsing, maintain consistent heat distribution, and act as a reducing agent for metals. Its versatility makes it indispensable for casting iron, copper, aluminum, and brass, while also serving as an efficient fuel source for industrial boilers.

Foundry coke's balance of high carbon content, moderate reactivity, and structural integrity ensures predictable combustion, enabling operators to control furnace temperatures accurately and maintain consistent metal quality. This makes it suitable for high-value casting operations where precision is critical.

Tip:Understanding the differences between foundry coke and metallurgical coke helps avoid inefficiencies and ensures consistent output in production.

Why Choose Foundry Coke?

Reliable Heat Output

One of the most compelling reasons foundries rely on foundry coke is its consistent and predictable heat output. In metal casting, maintaining uniform furnace temperatures is crucial for producing high-quality products. Variations in heat can cause defects such as porosity, surface cracking, and uneven metal density. Foundry coke burns steadily, generating sufficient thermal energy to sustain long smelting processes without fluctuations. This allows operators to maintain precise control over metallurgical parameters, ensuring that all zones of the furnace achieve the required temperature. Consistent heat also improves fuel efficiency, as the predictable combustion reduces energy waste and prevents unnecessary recharging of coke. High-grade foundry coke ensures that critical industrial operations, including iron, steel, and non-ferrous metal casting, run smoothly and produce reliable results every time.

Low Impurities for Superior Metal Quality

Foundry coke is valued for its low levels of sulfur and ash, which directly impact the quality of the final metal product. High sulfur content can lead to brittle alloys that are prone to cracking during cooling, compromising structural integrity. Excess ash contributes to slag formation, increases post-processing requirements, and can introduce impurities into molten metal. By using low-impurity foundry coke, foundries can significantly reduce these risks. This improves casting quality, minimizes waste, and lowers operational costs associated with slag removal and additional refining steps. Furthermore, low-sulfur, low-ash coke helps ensure compliance with stringent industry standards, particularly in high-precision applications like automotive, aerospace, and high-performance steel production. It allows metallurgists to produce cleaner, more consistent metals with optimal mechanical properties.

Structural Strength

The physical durability of foundry coke makes it ideal for sustaining high-temperature industrial processes. Large, dense blocks provide essential structural support within cupola furnaces, electric arc furnaces, and other high-heat setups. During long casting runs, maintaining block integrity is vital. If coke blocks break down or collapse, it can disrupt airflow, reduce furnace efficiency, and cause uneven heat distribution. Structural strength ensures that coke maintains its form under extreme conditions, supporting uniform gas flow and heat transfer. This stability not only protects the furnace infrastructure but also ensures that molten metal quality remains consistent. Operators can rely on strong foundry coke to withstand repeated heating cycles, reduce maintenance interruptions, and maintain uninterrupted production schedules.

Versatility Across Applications

Foundry coke’s versatility is another key advantage that makes it indispensable in modern industry. It is suitable for both ferrous and non-ferrous metal casting, serving as fuel, a reducing agent, and a carbon raiser. Its stable heat output allows it to be used in industrial boilers, cupola furnaces, and smelting operations, providing a single, reliable source of energy for multiple processes. This flexibility simplifies logistics and supply chain management, reducing the need for multiple fuel types and minimizing storage requirements. Additionally, operators can achieve consistent results across different production lines, whether producing iron castings, aluminum components, or specialty alloys. Its adaptability enhances operational efficiency and ensures repeatable quality across diverse metallurgical applications.

Tip:Always verify supplier test reports and certifications to ensure heat output and impurity levels meet operational standards.

Key Features of Foundry Coke

High Carbon Content

High fixed carbon content, usually above 85%, ensures optimal heat generation and carbon-raising in molten metals. This enables operators to control hardness, strength, and other metallurgical properties effectively. High-carbon coke also improves fuel efficiency, producing more heat per unit weight and reducing operational costs.

Low Sulfur and Ash

Sulfur and ash are critical factors affecting metal quality. Low sulfur levels (<1%) prevent brittleness in alloys, while minimal ash (<10%) reduces slag and contamination. These characteristics support cleaner production and reduce maintenance requirements.

Uniform Block Size

Consistent block size is essential for proper airflow and furnace stability. Oversized chunks support structural integrity, while smaller pieces enhance heat distribution. Uniform blocks prevent uneven combustion, optimizing furnace efficiency and metal quality.

Reactivity and Burn Rate

Foundry coke's moderate reactivity balances heat output and burn duration, maintaining a predictable temperature profile. Controlled combustion minimizes fluctuations, allowing for precise melting and alloying in both ferrous and non-ferrous casting.

Parameter | Typical Range / Standard | Importance for Casting |

Carbon Content | ≥ 85% | Enhances heat generation and carbon-raising |

Sulfur Content | ≤ 0.5% | Prevents brittleness in metal alloys |

Ash Content | ≤ 10% | Reduces slag and impurities |

Block Size | Large chunks (for structure) / Small chunks (for heat efficiency) | Supports furnace stability and airflow |

Reactivity | Moderate | Ensures consistent combustion |

Tip:Use specification tables to compare supplier products and ensure they meet production requirements.

Applications in Industry

Metal Casting

Foundry coke serves as both fuel and reducing agent in metal casting. Its high carbon content ensures rapid melting of iron, copper, and other metals, while stable heat reduces defects and enhances casting surface quality. This leads to improved yield and lower post-processing costs.

Steel and Iron Production

In blast furnaces, foundry coke acts as structural support and carbon source. Consistent airflow and heat distribution are crucial, and low-impurity coke reduces slag formation. High carbon and block integrity improve molten metal quality and furnace efficiency.

Cupola Furnaces

Cupola furnaces require coke that withstands prolonged high-temperature conditions. Foundry coke’s structural strength ensures long-duration stability without block collapse, maintaining consistent casting quality and repeatable results.

Non-Ferrous Casting

Non-ferrous metals like aluminum and brass require high purity. Foundry coke’s low sulfur and ash content prevent contamination, while stable heat output ensures uniform metal density, smooth surfaces, and minimal defects.

Industrial Boilers

Foundry coke can serve as a high-efficiency fuel for boilers. Its high carbon content and low impurities enable prolonged combustion, reducing fuel consumption and maintenance.

Evaluation Factor | Key Considerations |

Supplier Reputation | Experience, testimonials, global presence |

Product Range | Block size, carbon content, reactivity, impurity levels |

Quality Control Practices | Lab testing, certifications, detailed batch specifications |

Pricing and Terms | Cost vs quality, delivery reliability, bulk order options |

Tip:The versatility of foundry coke allows a single fuel source to support multiple industrial operations, simplifying supply chains.

How to Choose the Right Foundry Coke

Assessing Size and Reactivity

Proper block size selection balances structural support and heat distribution. Large chunks support furnace integrity, while smaller pieces enhance combustion efficiency. Evaluate furnace type, casting requirements, and airflow to determine optimal size. Reactivity should enable predictable burn rates and temperature control.

Evaluating Carbon, Sulfur, and Ash

High carbon ensures heat and carbon-raising efficiency. Low sulfur prevents brittle alloys, and minimal ash reduces slag. Consider these parameters according to your metal type and casting process.

Supplier Certification and Quality Assurance

Purchase from certified suppliers providing lab-tested documentation. Confirm block size, carbon content, sulfur, and ash levels. Consistent quality reduces operational risk and ensures reproducible metal properties.

Cost vs. Performance Balance

High-quality coke may cost more upfront but reduces defects, rework, and fuel usage. Evaluate purchase price alongside operational efficiency to maximize ROI. Regional availability and shipping costs should also factor into supplier selection.

| Selection Criteria | Recommendation |

| Block Size | Match furnace type and airflow |

| Carbon Content | ≥85% for optimal heat and metal quality |

| Sulfur Content | <1% to prevent brittleness |

| Ash Content | <10% to reduce slag |

| Supplier Documentation | Require certificates and test reports |

Comparing Top Suppliers

Supplier Reputation

When evaluating foundry coke suppliers, reputation is one of the most critical factors. Established suppliers with years of experience often demonstrate consistent quality and reliable service. Client testimonials, case studies, and industry references can reveal how dependable a supplier is in meeting delivery schedules and maintaining product standards. A supplier with a global presence is also better positioned to handle international logistics and provide prompt support if issues arise. Choosing a reputable supplier reduces the risk of production delays, inconsistent material quality, or supply chain disruptions, which can have costly consequences in large-scale foundry operations.

Product Range

The breadth of a supplier’s product range is essential for meeting diverse casting needs. Top suppliers offer variations in block size, carbon content, reactivity, and impurity levels to accommodate ferrous, non-ferrous, and industrial boiler applications. For instance, a steel foundry may require high-carbon, large-block coke for cupola furnaces, while non-ferrous operations prioritize purity and controlled reactivity. Suppliers with a diverse product catalog allow foundries to source the most appropriate coke type for each specific application without switching vendors. This flexibility helps streamline operations and ensures that each batch of molten metal meets the desired quality standards.

Quality Control Practices

Rigorous quality control distinguishes premium suppliers from less reliable ones. Leading foundry coke providers implement lab-tested, certified quality checks to ensure consistency in carbon content, sulfur levels, ash content, and block integrity. Many suppliers hold ISO or equivalent certifications, demonstrating their adherence to international production standards. Additionally, top suppliers provide detailed product specifications with each shipment, including chemical composition and physical characteristics. This transparency allows foundries to monitor performance, maintain metallurgical control, and avoid costly variations in their final metal products.

Pricing and Terms

Price is a crucial factor, but it should always be balanced against quality and reliability. The cheapest supplier may not provide consistent coke characteristics, while premium options can offer better long-term value by reducing waste, defects, and downtime. Compare pricing relative to delivery reliability, local availability, and seasonal fluctuations. Some suppliers offer bulk contracts or long-term agreements that stabilize pricing and secure supply during peak production periods. Evaluating both cost and performance ensures optimal ROI while maintaining operational efficiency and product quality.

Conclusion

Selecting the right foundry coke supplier requires careful evaluation of product specifications, quality assurance, and operational needs. High-carbon, low-sulfur, low-ash coke with uniform block size ensures stable furnace operation, consistent metal quality, and efficient production. Comparing suppliers based on certifications, lab reports, and reputation helps reduce risk, minimize defects, and optimize ROI. Foundry coke remains a critical material across metal casting, steel production, and industrial boiler applications, providing reliability, efficiency, and versatility for modern industrial processes.

This article explores the key factors in comparing Foundry Coke suppliers. It emphasizes supplier reputation, product range, quality control, and pricing. Tianjin Dahua Ocean International Trading Co., Ltd. provides high-quality foundry coke with consistent carbon content, low impurities, and diverse specifications, ensuring reliable performance across industrial applications. Choosing the right supplier reduces production risks and improves ROI, making their products a trusted choice for modern foundries.

FAQ

Q: What is Foundry Coke used for in industrial processes?

A: Foundry Coke serves as a fuel, carbon source, and structural support in metal casting and smelting, enhancing metal quality.

Q: How do I compare Foundry Coke suppliers?

A: Evaluate supplier reputation, product range, quality control, certifications, and pricing to ensure consistent supply.

Q: Why are low impurities important in Foundry Coke?

A: Low sulfur and ash reduce slag and prevent brittleness, improving casting outcomes and alloy performance.

Q: What specifications should I check before buying Foundry Coke?

A: Check carbon content, block size, sulfur, and ash levels. Ensure lab-tested documentation from reliable suppliers.

Q: How does pricing vary among Foundry Coke suppliers?

A: Pricing depends on quality, delivery, regional availability, and contract options for bulk orders.

Q: Can Foundry Coke be used for non-ferrous metals?

A: Yes, its stable heat and purity suit both ferrous and non-ferrous casting, as well as industrial boilers.