Introduction

Have you ever wondered how metal casting stays precise? Foundry Coke plays a key role in high-quality production. In this article, we explore its definition, features, and uses. You will learn why it matters and how to choose the right type.

What is Foundry Coke?

Definition and Production Process

Foundry coke is a high-carbon fuel derived from selected coal blends. The production process, known as carbonization, involves heating coal in a coke oven at temperatures between 1100°C and 1400°C in the absence of air. This process removes volatile compounds, leaving behind a dense, carbon-rich material capable of sustaining high temperatures over prolonged periods. The resulting coke is porous yet strong, enabling it to support heavy loads inside furnaces.

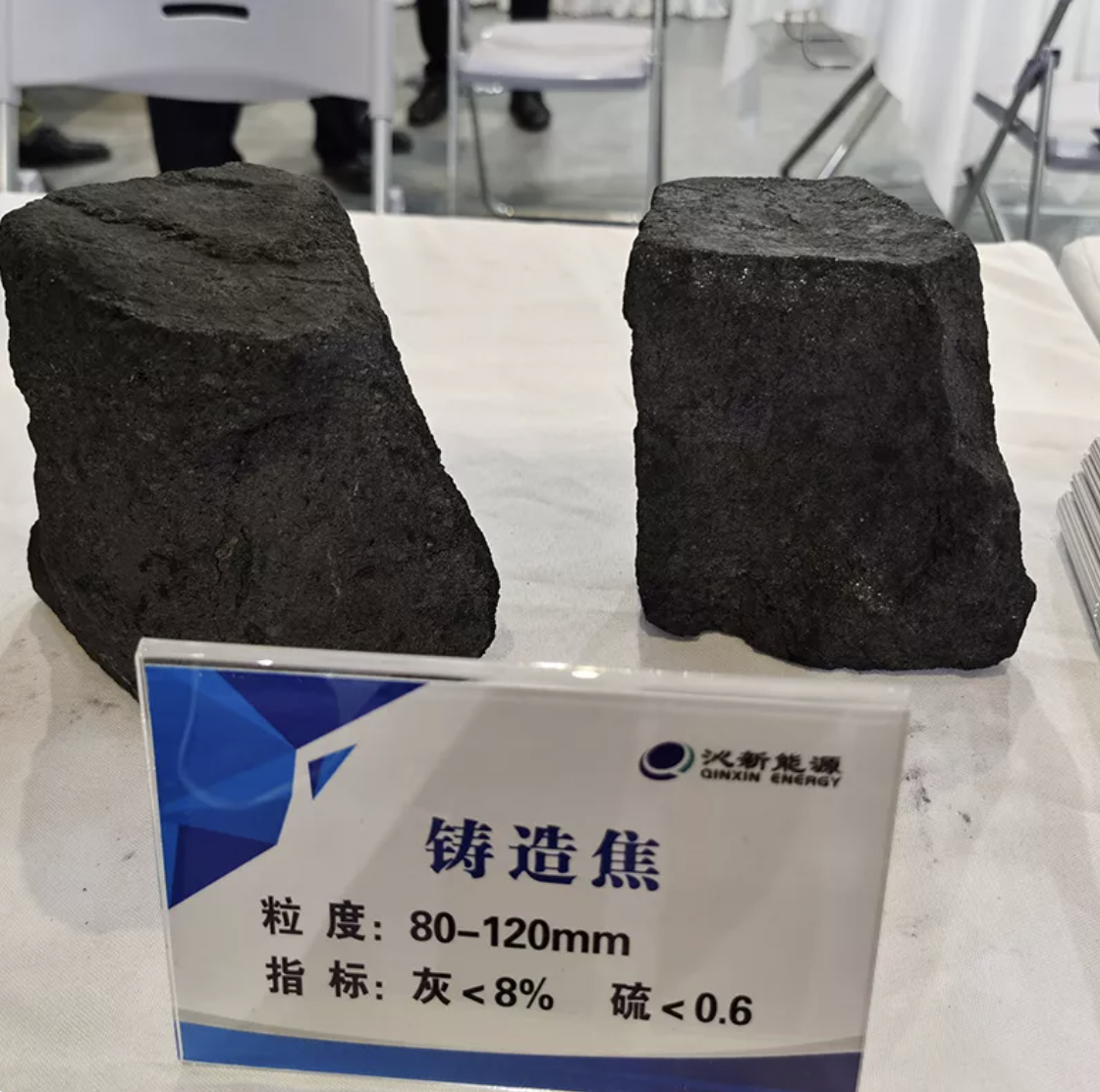

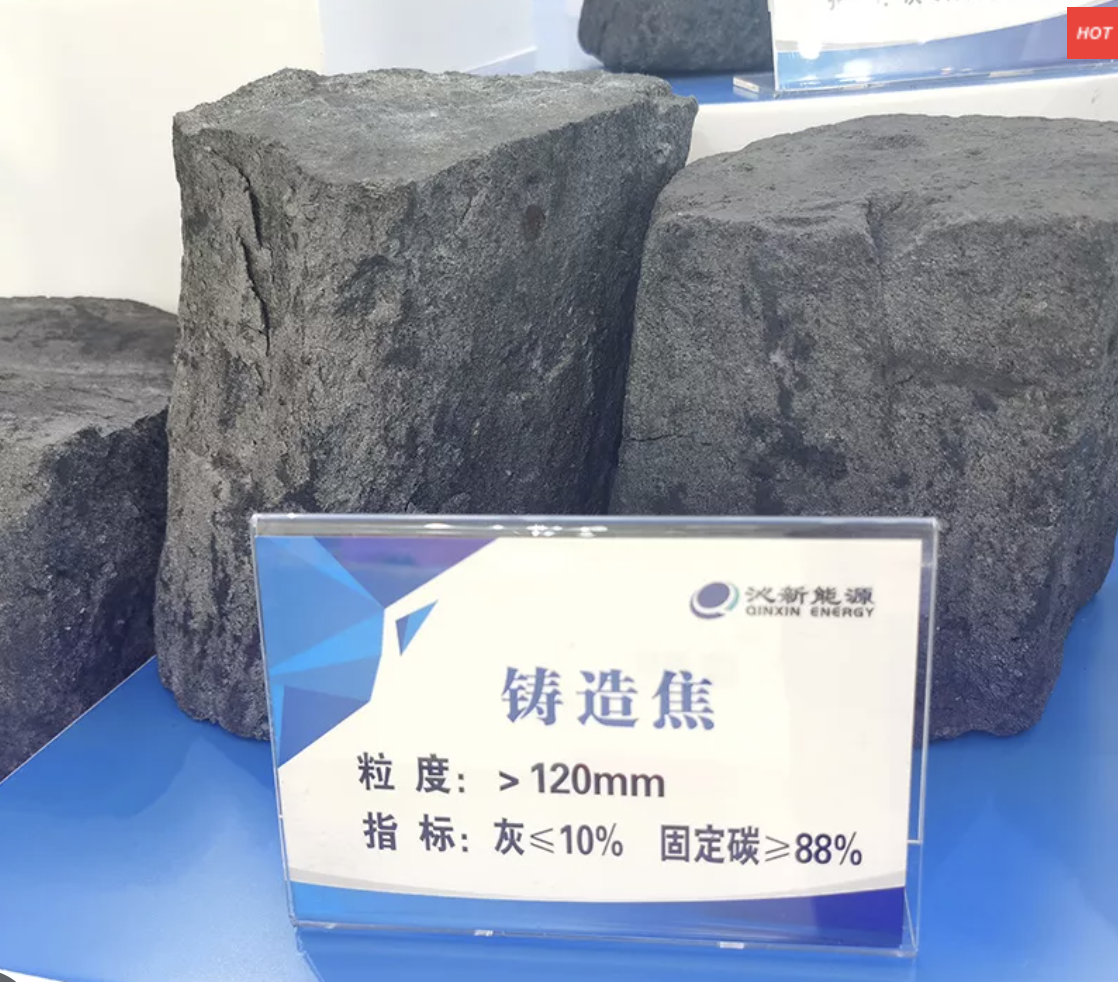

Compared to metallurgical coke, foundry coke is engineered to achieve specific physical and chemical properties. Its blocks are larger, with more uniform size and shape, and it contains lower levels of sulfur and ash. These characteristics allow it to perform consistently in high-demand casting processes, providing reliable heat output and maintaining structural integrity. Foundry coke's thermal stability ensures that furnaces operate efficiently without temperature fluctuations that could affect metal quality.

Tip: Foundry coke differs from metallurgical coke in block size, carbon content, and strength, making it the preferred choice for high-quality casting operations.

Differences Between Foundry Coke and Metallurgical Coke

While both foundry coke and metallurgical coke are derived from coal carbonization, their applications and properties differ significantly. Metallurgical coke is often used in blast furnaces for steel production, whereas foundry coke is designed for direct use in casting operations and cupola furnaces. Foundry coke emphasizes large block size, high carbon content (>85%), and low impurities to ensure structural support and clean combustion.

Metallurgical coke, on the other hand, may have slightly lower carbon content (80–85%) and smaller pieces, making it less suitable for operations that demand stable structural performance over long periods. Foundry coke’s low sulfur and ash content minimize metal contamination, reduce slag, and support environmental compliance. Additionally, its uniform block size allows even airflow and heat distribution, critical for producing high-quality castings consistently.

Feature | Foundry Coke | Metallurgical Coke |

Carbon Content | High (>85%) | Moderate (80–85%) |

Block Size | Large | Smaller |

Sulfur Content | Low | Higher |

Ash Content | Low | Higher |

Heat Stability | High | Moderate |

Structural Strength | Excellent | Adequate |

Primary Applications | Foundries, cupola furnaces | Blast furnaces, steel production |

Why Choose Foundry Coke?

Advantages in Heat Stability

Foundry coke provides stable and continuous heat during the metal melting process. Its high fixed carbon content ensures that furnaces reach the required temperatures quickly and maintain them consistently. This stability is critical in processes such as iron, copper, and non-ferrous metal casting. Without such reliability, the molten metal can experience uneven heating, leading to defects, incomplete melting, or structural weaknesses in the final product.

The consistent heat output also reduces energy consumption because the furnace does not require constant adjustments or repeated heating cycles. In large-scale operations, this energy efficiency translates into significant cost savings while maintaining high-quality standards. High-grade foundry coke supports both short and long casting runs, proving versatile for industrial operations with varying demands.

Low Impurities for Clean Casting

One of the primary reasons foundry coke is favored is its low sulfur and ash content. Impurities in the coke can introduce defects into molten metal, such as brittleness or inclusions, which compromise mechanical properties. Low ash content reduces slag formation, decreasing waste and improving metal purity. For high-grade steel production, controlling sulfur content is critical, as even minimal amounts can make alloys brittle.

Foundry coke's low impurity levels also minimize environmental impact by reducing emissions and particulate matter during combustion. These characteristics support compliance with increasingly strict environmental regulations and sustainability initiatives in the metal production industry.

Tip: Selecting low-ash, low-sulfur coke is essential for producing high-quality metals and meeting environmental standards.

Structural Integrity and Versatility

Foundry coke’s large, robust blocks maintain their shape under extreme heat, supporting furnace structure throughout the casting process. They are less prone to crushing or producing dust, which improves safety and efficiency. The combination of size, density, and strength ensures that industrial furnaces operate smoothly, even under prolonged high-temperature conditions.

Its versatility allows use in ferrous and non-ferrous casting, industrial boilers, and carbon adjustment in molten metals. This adaptability makes foundry coke a multi-purpose solution for industrial facilities, reducing the need for multiple fuel types and simplifying inventory management.

Key Features of Foundry Coke

High Carbon Content

High carbon content is the defining feature of foundry coke. Carbon acts as a primary fuel and a carbon-raising agent in molten metals, ensuring the final product has the desired hardness and structural properties. High carbon also guarantees rapid heat generation, which is critical for industrial operations that require fast and uniform melting of metals.

This characteristic enables consistent production outcomes, reducing the likelihood of defects. The high carbon content also allows foundry coke to sustain prolonged heat, making it suitable for long casting cycles in cupola furnaces or smelting operations.

Low Impurity Levels

Low ash and sulfur levels prevent contamination in molten metal. Ash contributes to slag, while sulfur can create brittleness in metal alloys. By minimizing these impurities, foundry coke supports cleaner casting, improves surface finish, and enhances the mechanical strength of final products.

Low impurities also reduce environmental impact by limiting particulate emissions. For industries aiming for sustainable operations, choosing high-quality foundry coke ensures compliance with emission standards.

Strength and Structural Stability

Foundry coke blocks are engineered for maximum strength. They resist crushing, maintain their shape during combustion, and support the physical structure of furnaces. This durability is essential in high-demand operations where furnace integrity directly affects productivity and product quality.

The consistent block size allows even heat distribution, improving airflow and reducing hotspots. Strong coke blocks also reduce coke dust, which can clog furnaces and complicate maintenance.

Uniform Size and Reactivity

Uniform block size ensures controlled airflow and consistent heat in cupola furnaces. Moderate reactivity prevents sudden temperature spikes, which could damage molten metal or produce uneven casting.

This consistency improves energy efficiency, reduces fuel waste, and enables more precise temperature management in industrial operations.

Environmental Advantages

Foundry coke’s low volatility and reduced emissions support green foundry initiatives. Its combustion produces less smoke and fewer harmful gases, aligning with modern environmental standards. Companies adopting low-emission coke reduce their environmental footprint and enhance corporate responsibility profiles.

Applications in Industry

Metal Casting

Foundry coke plays a critical role in metal casting as both a fuel and a reducing agent. It is used extensively in producing iron, copper, aluminum, and other non-ferrous metals. Its stable combustion ensures uniform heat distribution, which is crucial for melting metals evenly and avoiding defects such as porosity, cracks, or uneven surface texture. High-value casting industries, including automotive and aerospace components, rely on foundry coke to maintain consistent quality. By providing predictable heat and carbon content, it reduces the need for extensive post-processing and finishing, saving both time and operational costs.

Iron and Steel Production

In blast furnace operations, foundry coke functions as a carbon source and structural support. Its high carbon content supports efficient metallurgical reactions, while its low sulfur and ash levels minimize slag formation. This combination improves heat distribution and overall furnace efficiency, resulting in higher-quality iron and steel production. Steel mills often select coke based on its ability to withstand extreme temperatures without breaking down, ensuring a continuous and stable smelting process. By enhancing both thermal efficiency and material quality, foundry coke directly contributes to cost-effective and reliable steelmaking operations.

Cupola Furnaces

Cupola furnaces demand coke with uniform size, high strength, and structural integrity. Foundry coke fits this requirement by providing consistent heat while maintaining its block structure over extended high-temperature runs. Its resistance to pulverization reduces dust production, which can otherwise interfere with airflow and affect melting efficiency. Reliable cupola operation ensures repeatable casting outcomes, which is especially important in iron foundries producing heavy machinery parts, pipes, and engine components.

Carbon Additive in Smelting

Foundry coke also serves as a carbon additive, allowing operators to fine-tune the carbon content of molten metals. By controlling the amount of coke added, manufacturers can influence the hardness, strength, and other key properties of the final product. This flexibility is essential for producing multiple grades of steel or iron to meet specific mechanical and structural requirements. For example, higher carbon content is desirable for cast iron, while lower carbon is preferred for steel alloys used in construction or automotive applications.

Industrial Boilers

Beyond metallurgical applications, foundry coke is employed as a fuel source in industrial boilers. Its high carbon content and low impurity levels provide efficient, long-duration heat, which is ideal for heating systems in foundries and related industrial facilities. Using foundry coke in boilers reduces fuel consumption, minimizes residue build-up, and lowers maintenance requirements. Its predictable combustion characteristics also simplify temperature management and improve operational consistency.

Tip: Foundry coke’s versatility across multiple applications reduces the need for separate fuel types, streamlines logistics, and supports cost-efficient operations across metal casting, steel production, and energy generation.

Application | Coke Size | Carbon Content | Sulfur Content | Ash Content | Key Requirement |

Metal Casting | Mixed (small + large) | High (≥85%) | Low (<1%) | Low (<10%) | Uniform melting, minimal defects, consistent quality |

Iron & Steel Production | Large chunks | High (≥85%) | Low (<1%) | Low (<10%) | Structural support, efficient heat, reduced slag |

Cupola Furnaces | Uniform large | High (≥85%) | Low (<1%) | Low (<10%) | High structural integrity, long-duration heat |

Carbon Additive in Smelting | Variable | Adjustable | Low (<1%) | Low (<10%) | Control hardness, strength, and metal properties |

Industrial Boilers | Small/medium | High (≥85%) | Low (<1%) | Low (<10%) | Efficient fuel, stable combustion, low maintenance |

How to Choose the Right Foundry Coke

Coke Size

Selecting the correct coke size is critical for both furnace efficiency and structural stability. Large chunks of coke provide robust support for the charge in cupola furnaces or blast furnaces, preventing collapse during high-temperature operations. Smaller pieces, however, allow for faster and more uniform heat distribution, improving combustion efficiency and reducing hotspots. Using a well-balanced mix of sizes can optimize airflow and ensure consistent thermal performance. For instance, steel foundries often prefer a blend where 60–70% are larger chunks and the remainder smaller, ensuring both support and efficient burning.

Carbon, Sulfur, and Ash Content

The chemical composition of foundry coke significantly impacts metal quality. High carbon content is essential for maintaining stable heat and for carbon-raising in the molten metal. Low sulfur content prevents the formation of brittle sulfide inclusions, which could compromise steel or iron strength. Low ash content reduces slag production, leading to cleaner metals and lower maintenance for furnaces. Each application has its own optimal parameters: ferrous metals prioritize structural stability and high carbon, while non-ferrous metals, like aluminum or copper, require ultra-low impurities to prevent contamination. Testing and verifying these levels ensures the coke meets the specific metallurgical requirements.

Application Requirements

Different industrial processes have unique coke requirements:

● Non-Ferrous Metals: Require high-purity coke with minimal sulfur and ash to avoid alloy contamination and ensure uniform melting.

● Steel Casting: Emphasizes block strength and high carbon content to maintain furnace stability and achieve precise carbon levels in the final product.

● Industrial Boilers: Focus on fuel efficiency and consistent burn rate, where uniform coke size and predictable combustion are key. Understanding the precise needs of each application helps in choosing the most suitable foundry coke and avoiding costly production issues.

Supplier Quality

The reliability of your foundry coke supplier is just as important as the coke itself. Certified, lab-tested products provide documentation of block size, carbon, sulfur, and ash levels, ensuring reproducibility in industrial operations. Reputable suppliers also offer traceable quality certificates and test reports, helping you verify the product’s suitability before bulk purchasing. Reliable sourcing reduces operational risks, prevents furnace damage, and guarantees consistent casting results.

Tip: Always request test reports, certifications, and sample batches from suppliers before committing to large orders. This ensures the coke aligns with your application requirements and prevents surprises during production.

Conclusion

Foundry coke is crucial for high-quality metal casting. It provides stable heat and low impurities, ensuring better metal quality and furnace efficiency.Tianjin Dahua Ocean International Trading Co., Ltd. offers premium foundry coke that enhances production, reduces waste, and supports consistent, reliable results in industrial operations.

FAQ

Q: What is Foundry Coke?

A: Foundry Coke is a high-carbon fuel used in metal casting. It provides stable heat and low impurities for reliable furnace performance.

Q: How does Foundry Coke differ from Metallurgical Coke?

A: Foundry coke has larger blocks, higher carbon, and lower sulfur and ash. These coke characteristics make it ideal for cupola furnaces.

Q: What are the main uses of Foundry Coke?

A: Foundry coke serves as fuel, carbon additive, and structural support in iron, steel, and non-ferrous metal casting.

Q: Why choose high-quality Foundry Coke?

A: Premium foundry coke enhances metal purity, reduces slag, and maintains consistent furnace efficiency.

Q: How do coke characteristics affect casting?

A: Uniform size, high carbon content, and low impurities ensure steady heat, strong castings, and minimal waste.

Q: Can Foundry Coke be used for non-ferrous metals?

A: Yes, coke for foundry applications works for aluminum, copper, and brass due to stable heat and low impurities.